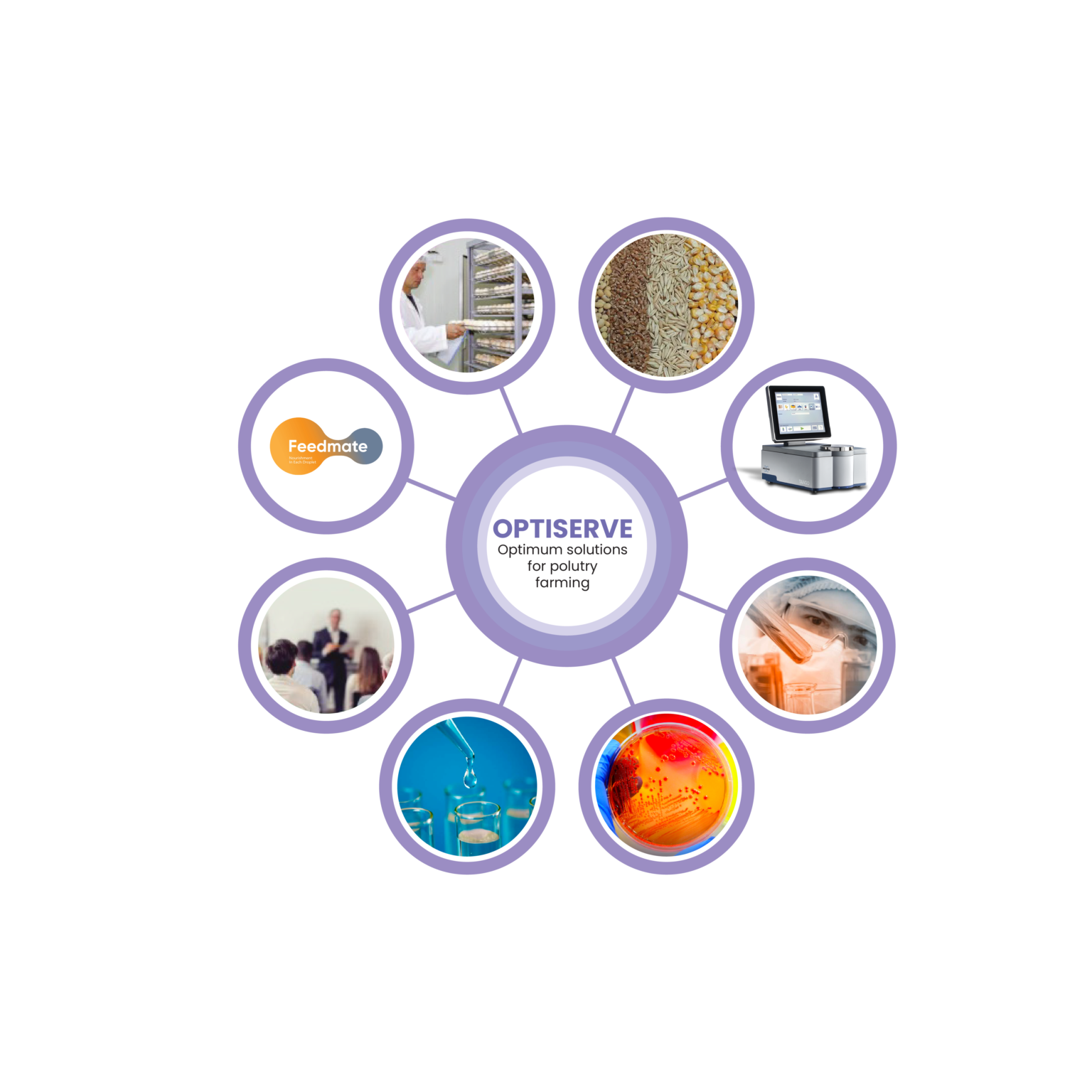

Optiserve

- Home

- Optiserve

With modern high performance poultry breeds, concern related to disease Incidence has also increased. Constantly increasing feed ingredient prices; demand optimization of poultry farming, which is not possible without the assistance of modern and dedicated laboratory services and expert intervention.

Optima understood the need of the hour and hence came up with OptiServe. Through OptiServe, works with poultry producers and guides them to achieve their goals by providing sustainable practical solutions in broilers, commercial layers, breeders, hatchery units, feed-mills, broiler integration and processing units with skilled human resources, subject specialists, innovative products and R&D units.

01 Feed Formulation

Feed Formulation Support

02 Near Infrared Spectroscopy (NIR)

Variability in raw materials brings challenges and NIR can be used to understand this to help ensure animals receive adequate nutrition. NIR provides greater insight into the nutritional value of feed and enables real-time decision-making for enhanced quality and higher productivity.

Analysis-

Moisture, Crude Protein, Crude Fat/Oil, Crude Fibre, Total Ash

03 Wet Chemistry

| Analysis Code | Name of the Test | Method of Analysis |

| O/P/01 | Moisture | Wet Chemistry & NIR |

| O/P/02 | Crude Protein | Wet Chemistry & NIR |

| O/P/03 | Ether Extract | Wet Chemistry & NIR |

| O/P/04 | Total Ash | Wet Chemistry & NIR |

| O/P/04 | Crude Fibre | Wet Chemistry & NIR |

| O/P/04 | Acid Insoluble Ash | Wet Chemistry & NIR |

| O/P/04 | Nitrogen Free Extract | By Difference |

| Analysis Code | Name of the Test | Method of Analysis |

| O/My/01 | Aflatoxins | Antigen Kits |

| O/P/02 | Ochratoxins | Antigen Kits |

| O/My/03 | T2 toxins | Antigen Kits |

| Analysis Code | Name of the Test | Method of Analysis |

| O/Mi/01 | Calcium | Wet Chemistry |

| O/Mi/02 | Phosphorus | Wet Chemistry |

| Analysis Code | Name of the Test | Method of Analysis |

| O/FFA/01 | Free Fatty Acids | Wet Chemistry |

| O/PV/02 | Peroxide value | Wet Chemistry |

| Iodine Value | Iodine Value | Wet Chemistry |

| Analysis Code | Name of the Test | Method of Analysis |

| O/SQ/01 | Urease Activity | Wet Chemistry |

04 Microbiology

| Analysis Code | Name of the Test | Method of Analysis |

| O/Mic/01 | Differential Counts | Plate Culture |

| O/Mic/02 | Clostridial spp. Count | Plate Culture |

| O/Mic/03 | E. Coli spp. Countt | Plate Culture |

| O/Mic/04 | Salmonella spp. Count | Plate Culture |

| O/Mic/05 | Total Coliform spp. Count | Plate Culture |

| O/Mic/06 | Total Viable Count (TVC) | Plate Culture |

| O/Mic/07 | MPN | Plate Culture |

| O/Mic/08 | Molds & fungus | Plate Culture |

05 Drinking Water Analysis

| Analysis Code | Name of the Test | Method of Analysis |

| O/WQ/01 | Water pH | pH meter |

| O/WQ/02 | Total Dissolved Solids(TDS) | Test kit |

| O/WQ/03 | Water activity | Wet Chemistry |

06 Technical Services and Training

Optima provide technical services and training to our customers in the poultry industry. This includes offering expertise and guidance in areas such as animal health, nutrition, and management practices. Our aim is to equip our customers with the knowledge and skills necessary to achieve their goals and improve the overall performance of their operations. Through our technical services and training programs, we strive to foster long-term partnerships with our customers and support their success in the industry.

07 Milling Solutions

To ensure feed mill efficiency & feed quality Optima come up with a range of unique products & exclusive feed milling services under the Feedmate Div it includes Feed milling audits Services, Feed mill biosecurity, Training, QA-QC management which helps customer to ensure smooth operations & quality feed production

Analysis-

Feed-mill Audit & Scoring, QA/QC Management, Laboratory Audit, Storing Management, Milling Biosecurity

08 Hatchery Audit